NEWS

ABOUT US

RENATUS ROBOTICS Corporation is a carve-out corporation of the TRUST SMITH Group,

an AI and robotics company from the University of Tokyo.

It utilizes cutting-edge technology to manufacture and sell ultra-efficient automated warehouses.

RENATUS ROBOTICS Corporation is a carve-out corporation of the TRUST SMITH Group,

an AI and robotics company

from the University of Tokyo.

It utilizes cutting-edge technology to manufacture

and sell ultra-efficient automated warehouses.

BUSINESS

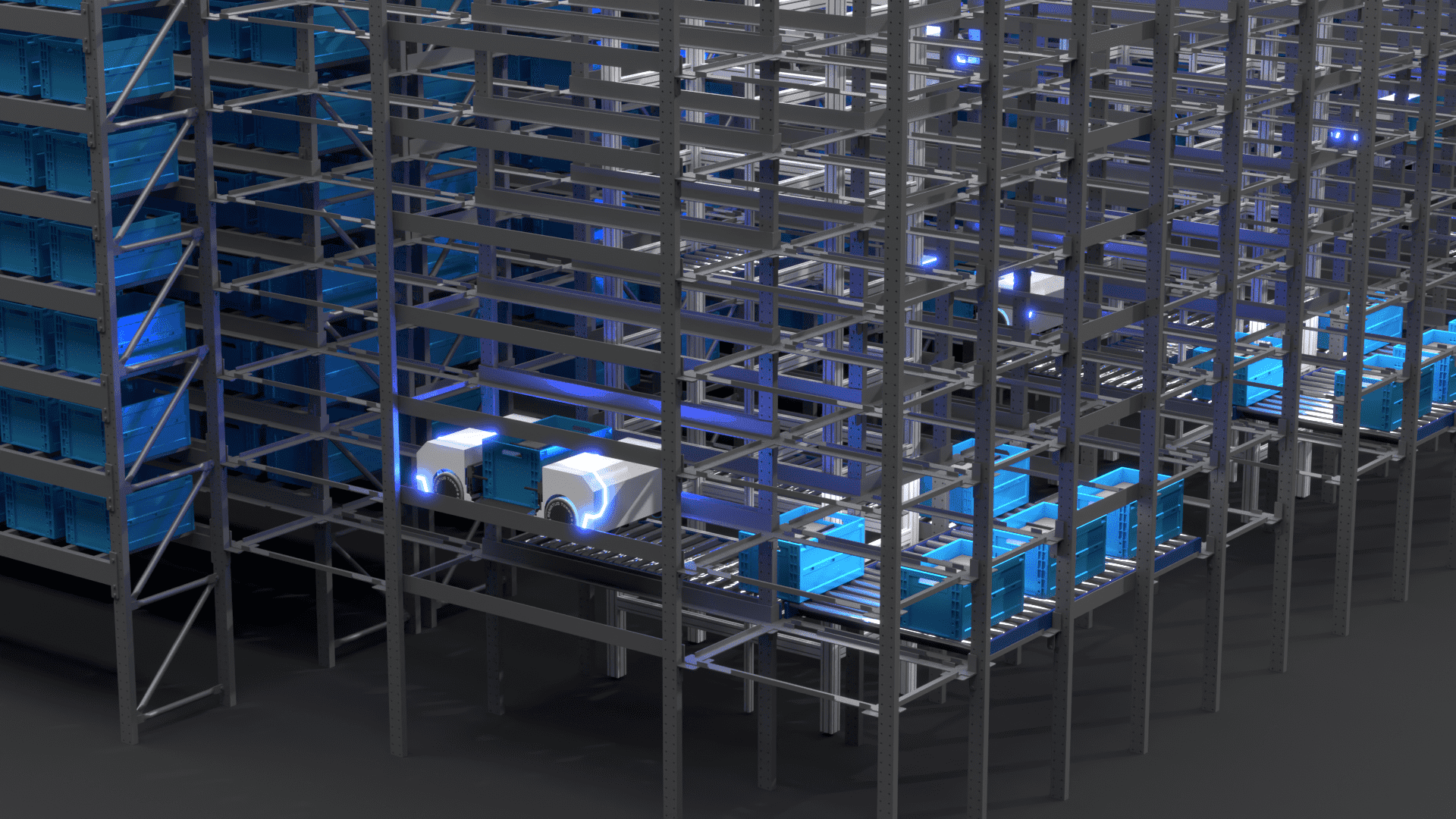

Project to establish a “next-generation warehouse”

utilizing state-of-the-art robotics/mathematical algorithm technology

Project to establish a “one-stop packaging next-generation warehouse”

utilizing state-of-the-art robotics/mathematical

algorithm technology

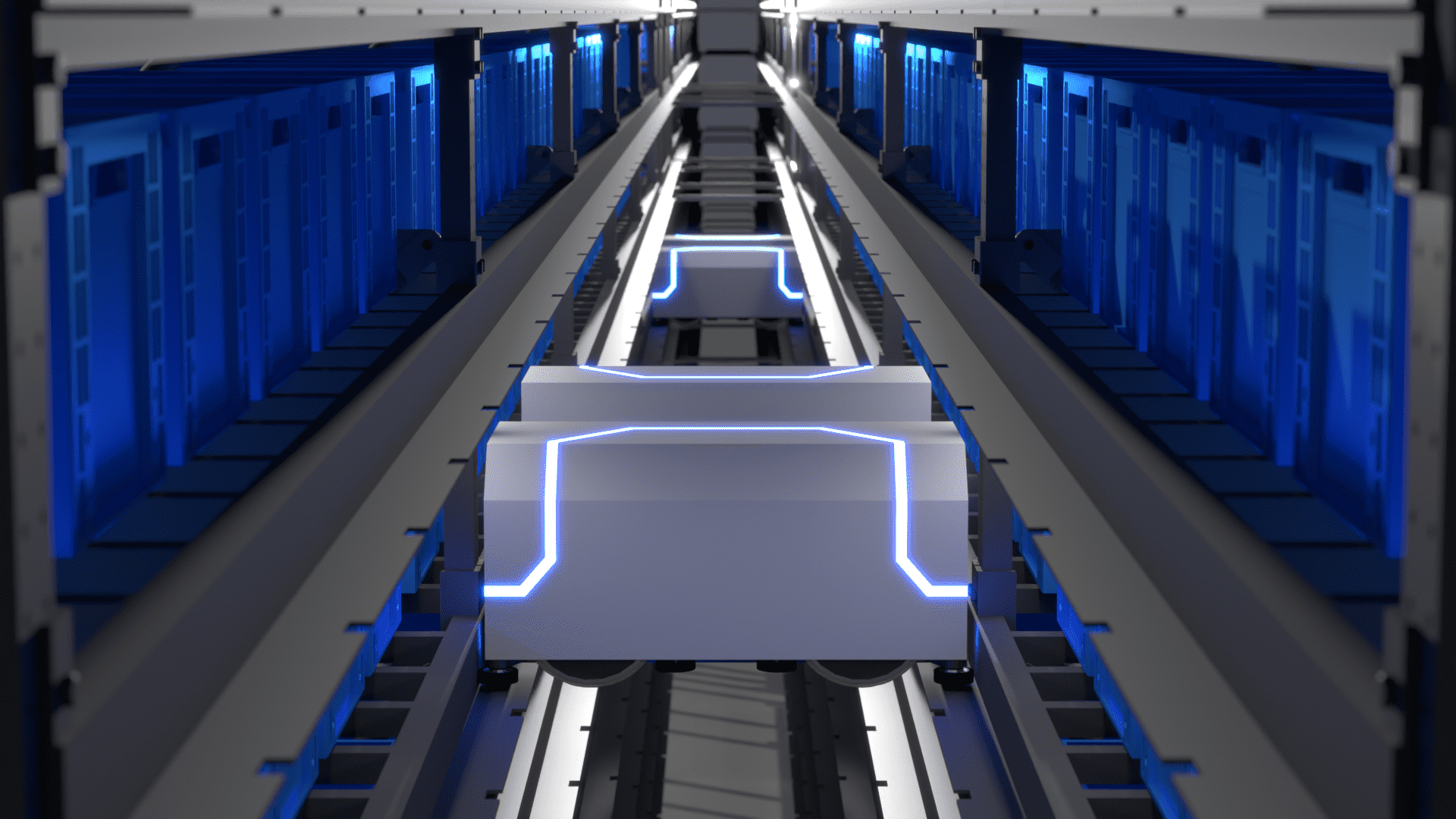

Utilizing the industry’s fastest class shuttles, lifting units, simultaneous control algorithms,

and other cutting-edge technologies, RENATUS realizes “one-stop packing,” in which picking,

consolidating, and packing are all performed by a single worker.

RENATUS, an automated warehousing system with the world’s highest level of cost performance,

contributes to solving labor shortages and reducing labor costs faced by logistics companies.

Utilizing the industry’s fastest class shuttles,

lifting units, simultaneous control algorithms,

and other cutting-edge technologies,

RENATUS realizes “one-stop packing,” in which

picking, consolidating, and packing are

all performed by a single worker.

RENATUS, an automated warehousing system

with the world’s highest level of cost performance,

contributes to solving labor shortages

and reducing labor costs faced by logistics companies.

SYSTEM

RENATUSCORTEX

optimization algorithm

detail

Advanced algorithms enable fleet control of 2000 robots, the largest in the industry, and RENATUS is the first product in the world to put algorithms to practical use that enable all robots to move at high speed along a semi-optimal route.

is possible only at surviving points

in the event of equipment failure

detail

RENATUS CORTEX monitors the status of all equipment. If some robot, lift, or other equipment fails, it instantly calculates an in/out pathway that bypasses the failed part, allowing the system to continue operation without stopping the entire system until it is restored, as in the past.

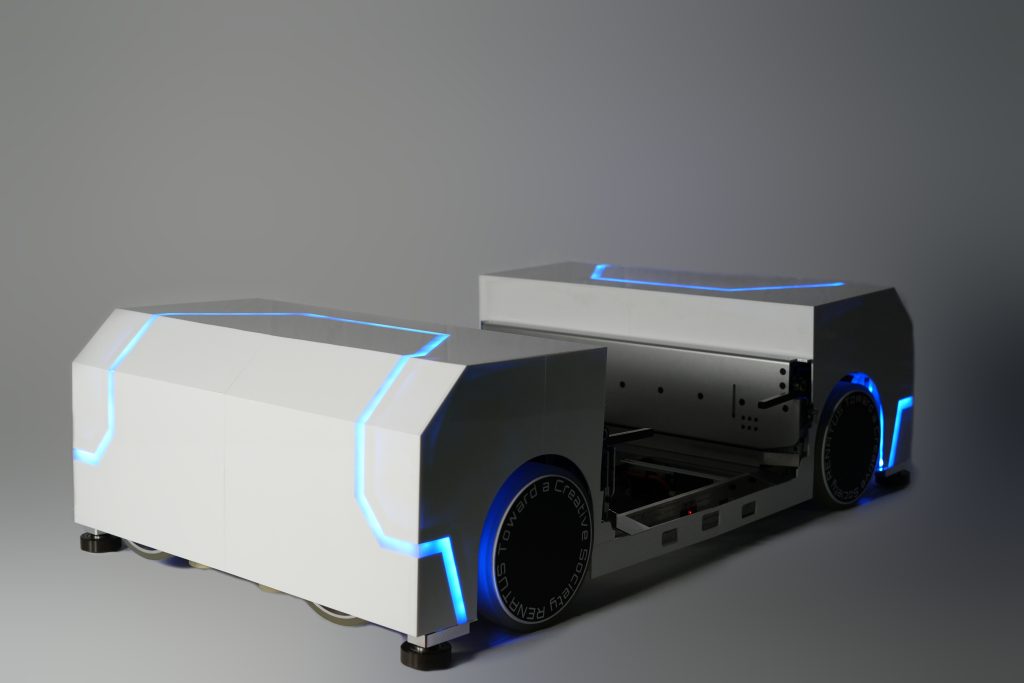

RENATUS SHUTTLE

for optimization

achieves

the industry’s fastest travel

and positioning down

to the millimeter

detail

The robot equipped with a high-power motor moves at the industry’s fastest speed of 4 m/s. By stepping on and off the vertical and horizontal grid rails laid out on the shelves, the robot transports the products along the shortest route at the fastest speed.

of goods

by unique

high-speed transfer module

detail

The high output transfer module can load and unload containers in 5 seconds. Advanced sensors built into the robot monitor container status to ensure safe and fast transshipment.

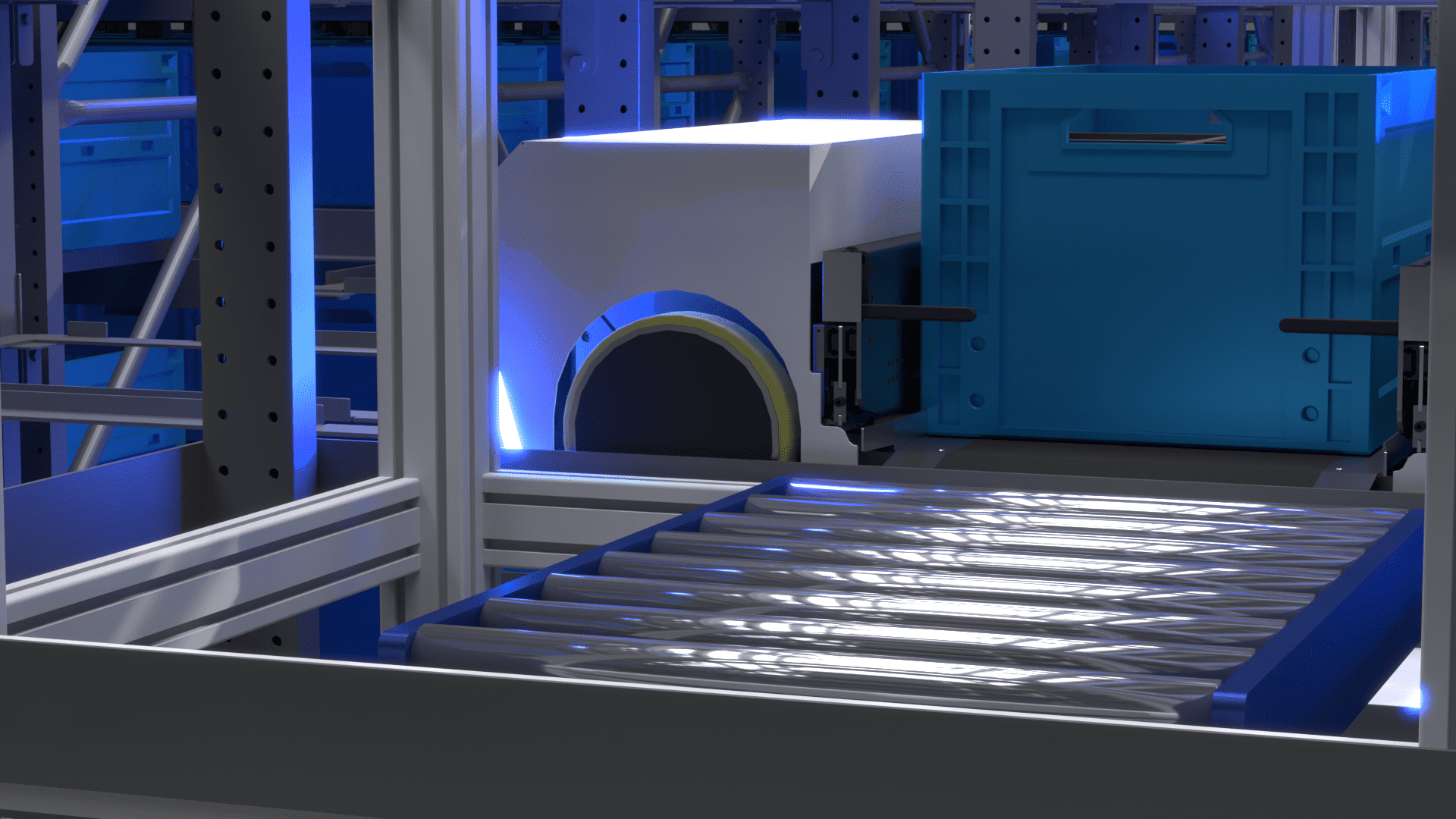

RENATUS STATION

improves work efficiency

detail

A continuous supply of pre-ordered containers and appropriate shipping cardboard is always available. One-stop, immediate completion of (1) piece picking, (2) cargo matching, and (3) packing.

from monotonous work

detail

High-speed picking robots can be introduced to unmanned and speed up the process of picking items that require high frequency incoming and outgoing shipping instructions. Our proprietary algorithm enables high-speed transfer of complex cargoes as well.

RENATUS RACK

and flexible layout

detail

Partitions can be built into the containers to further reduce the area. Customization is also possible according to the customer’s warehouse volume and shape.

instantly

transfers goods

to the packing operator

detail

Our proprietary high-speed elevating lift achieves the industry’s fastest vertical transfer speed of 4 m/s. Cargo is instantly moved between shelves and stations.

PVPRODUCT PROMOTIONAL VIDEO

FEATURESof RENATUS ROBOTICS

A single worker can pick 500 lines per hour.

In addition, the consolidation and packing

are completed at the same time as the picking.

Due to the unique shelf structure,

there is virtually no limit to the number

of containers that can be stored.

One-stop packing

detail

A single worker can pick 500 lines

per hour.

In addition,

the consolidation

and packing are completed

at the same time

as the picking.

Storage Efficiency

detail

Due to the unique

shelf structure,

there is virtually

no limit to the

number of containers

that can be stored.

Strength

- 01 AGV Price

-

Simple design suitable for mass production without a climbing mechanism

- 02 Storage Price

-

Inexpensive proprietary elevator. No need for gears or trolleys

- 03 Scalability

-

No traffic jams due to optimal shelf design and proprietary control software

- 04 AIPS

-

AIPS is possible on the large rack due to lack of traffic congestion

|01 AGV Price

Simple design suitable for mass production without a climbing mechanism

|02 Storage Price

Inexpensive proprietary elevator. No need for gears or trolleys

|03 Scalability

No traffic jams due to optimal shelf design and proprietary control software

|04 AIPS

AIPS is possible on the large rack due to lack of traffic congestion

TECHNOLOGY of TRUST SMITH Group

Obstacle Avoidance Arm Robots

General-purpose autonomous driving Algorithm-equipped AGVs

Video Data Automatic Masking AI

No learning required, model-less Picking System

1000-unit scale AGV Optimal Control Algorithm

By Image Recognition Automatic Inspection System

CONTACTRealizing the Ideal Fully

Automated Smart Warehouse

We will do our best to provide the best support

for your issues and requirements.

Please feel free to contact us.

We will do our best

to provide the best support

for your issues and requirements.

Please feel free to contact us.